Materials

Structural steels, alloy steels, stainless steels, aluminium, cast iron, polymers and engineering plastics.

Other materials available on request.

Processed according to customer specifications.

Delivering precision CNC-machined components, welded structures and complete sub-assemblies — from single parts to complex industrial assemblies — with certified quality and strong engineering support.

Precision CNC Machining

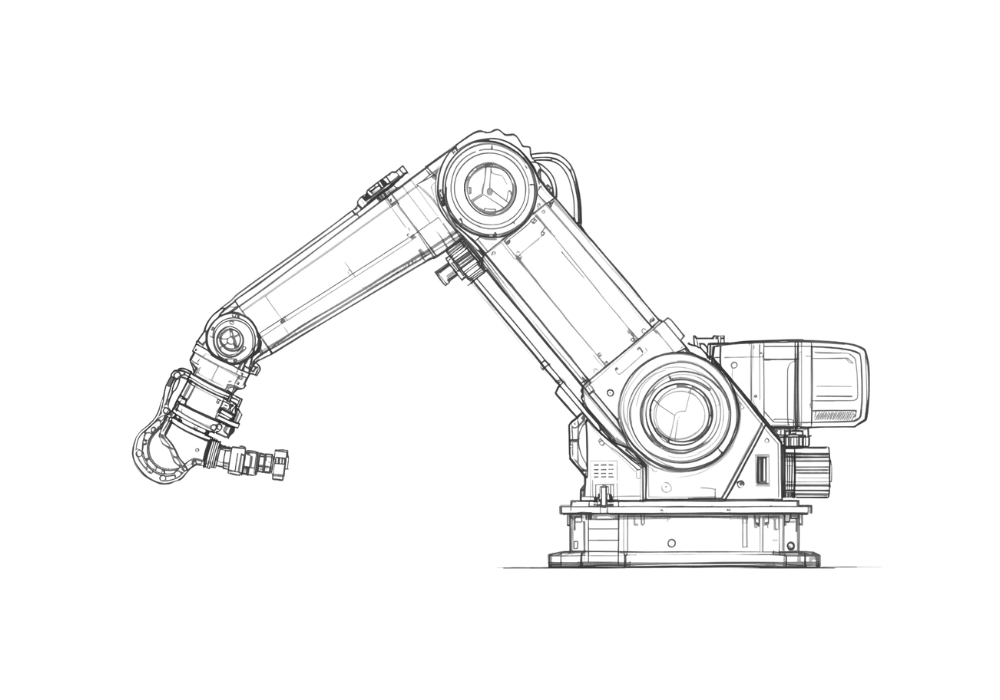

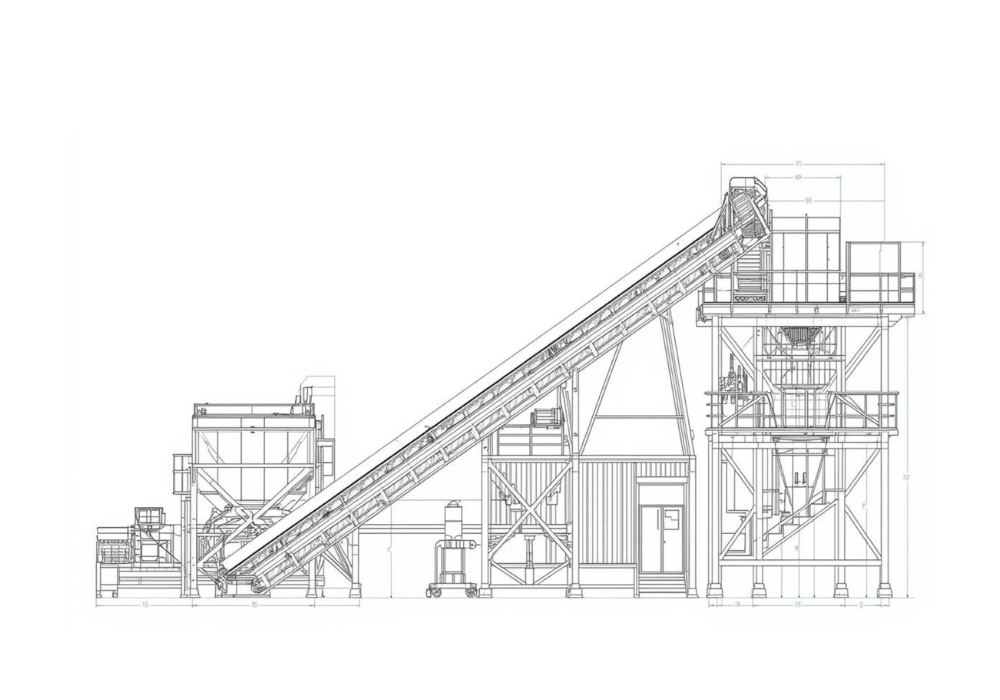

Welded Structures & Assemblies

Precision machining and welded steel structures — engineered with discipline, delivered with consistency.

Founded in 1999, NICMAR-DANCI is an independent, family-owned manufacturer from Bistrița, Romania, specializing in CNC machining, precision-milled and turned components, and welded steel constructions. We support European manufacturers and industrial equipment producers, including OEMs and Tier-1 suppliers, across a broad range of standard and high-requirement industrial applications.

Over more than two decades, we have expanded from a small workshop into a modern, vertically integrated production facility. Our capabilities combine CNC turning, milling and boring with engineered welded structural assemblies and dimensional inspection processes, ensuring predictable accuracy and reliable repeatability.

With the agility of a family-run organization and the discipline of an industrial supplier, NICMAR-DANCI provides flexible batch sizes, transparent technical communication and dependable lead times — building long-term manufacturing partnerships across Europe.

Integrated CNC machining and welded structural assemblies capabilities for industrial components and assemblies, from precision-machined parts to large-scale structures.

Complex prismatic components with controlled geometry, surface integrity and repeatability.

Rotational components engineered for load-bearing and function-critical applications.

Precision alignment and machining of large, heavy and welded components.

CNC cutting and bending of tubes and profiles, engineered for repeatability in welded structures and assemblies.

Controlled thermal cutting for structural steel parts and assemblies.

Certified welded assemblies for load-bearing and structurally critical applications.

Activities that strengthen our core manufacturing processes and project delivery.

Mechanical scope as standard. Hydraulic and electrical system integration available upon request.

NICMAR-DANCI operates certified welding and steel structure manufacturing processes supported by a documented quality management system, enabling repeatable quality, CE-marked structures and controlled traceability.

EN 1090-1, EN 1090-2 and ISO 3834-2 certified steel structures, frames and welded assemblies for heavy-duty equipment and industrial applications.

ISO 9001:2015 quality management system with documented processes, regular customer and third-party audits, and controlled serial production.

Dimensional inspection and 3D arm measurements, supported by material certification and batch traceability on request – aligned with customer inspection and documentation requirements.

Certificates, inspection records, and process documentation are available upon request to support customer audits and supplier qualification processes.

Industries aligned with our precision machining and welded assembly capabilities

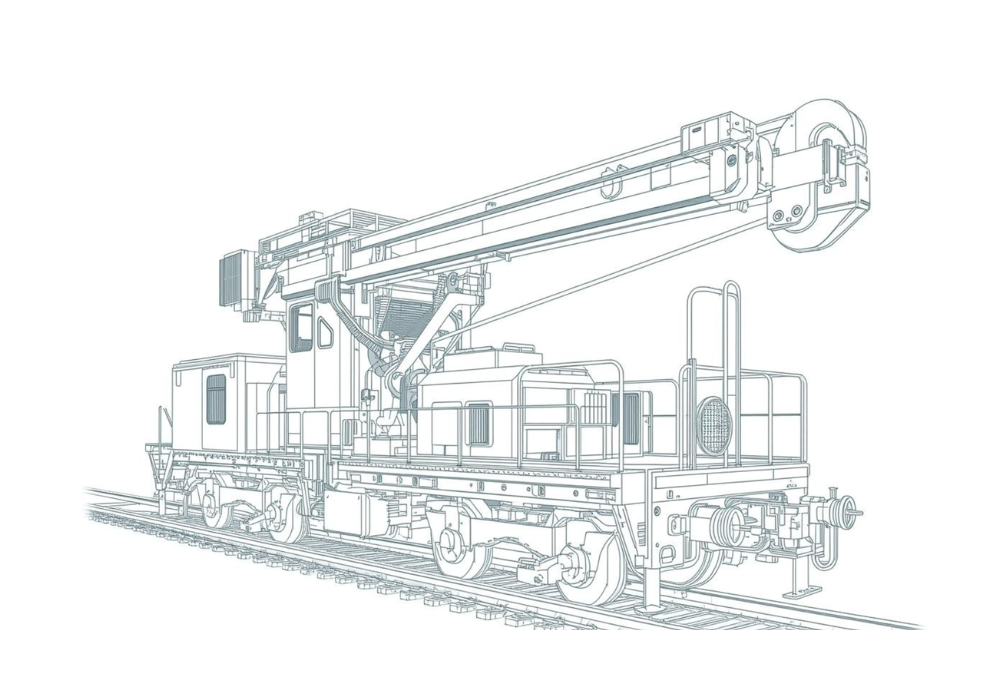

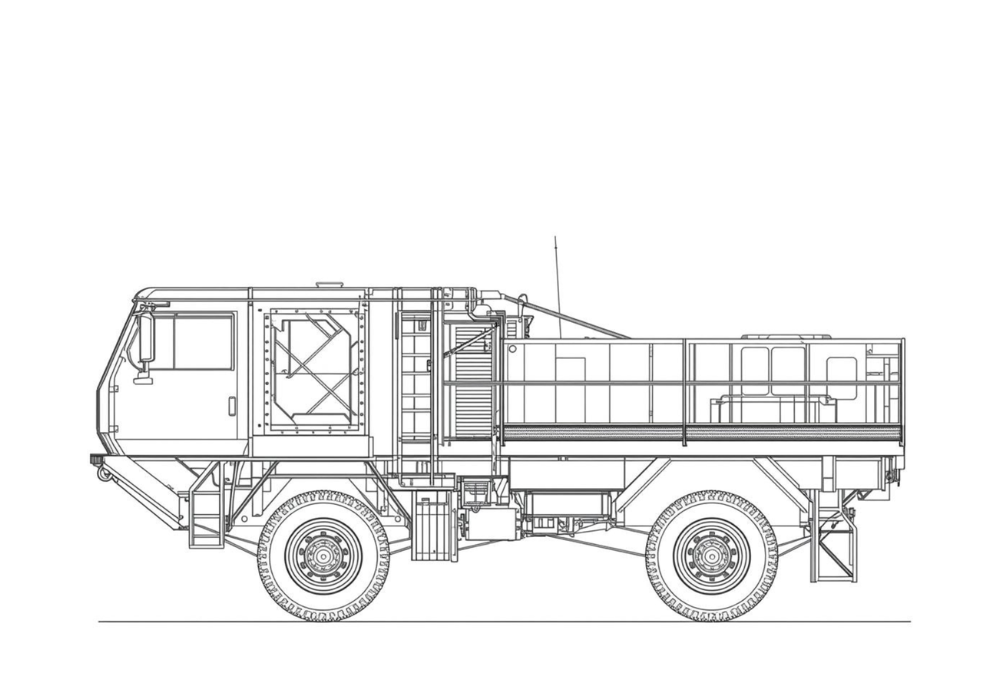

Our manufacturing capabilities are aligned with heavy-duty equipment applications, supporting precision machining and welded structural assemblies suitable for high-load and demanding operating conditions.

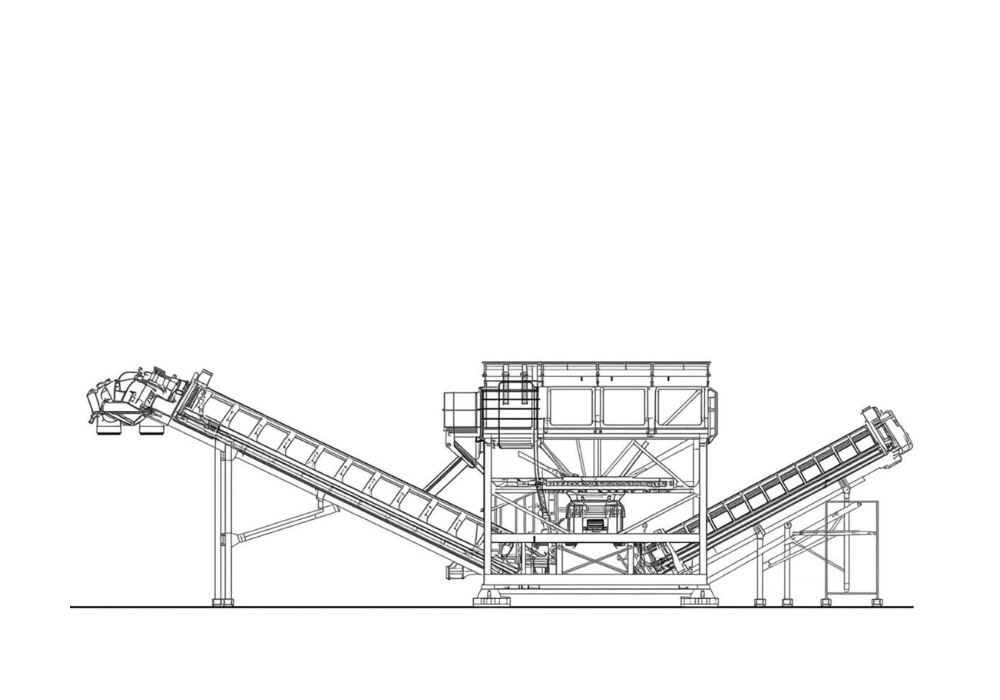

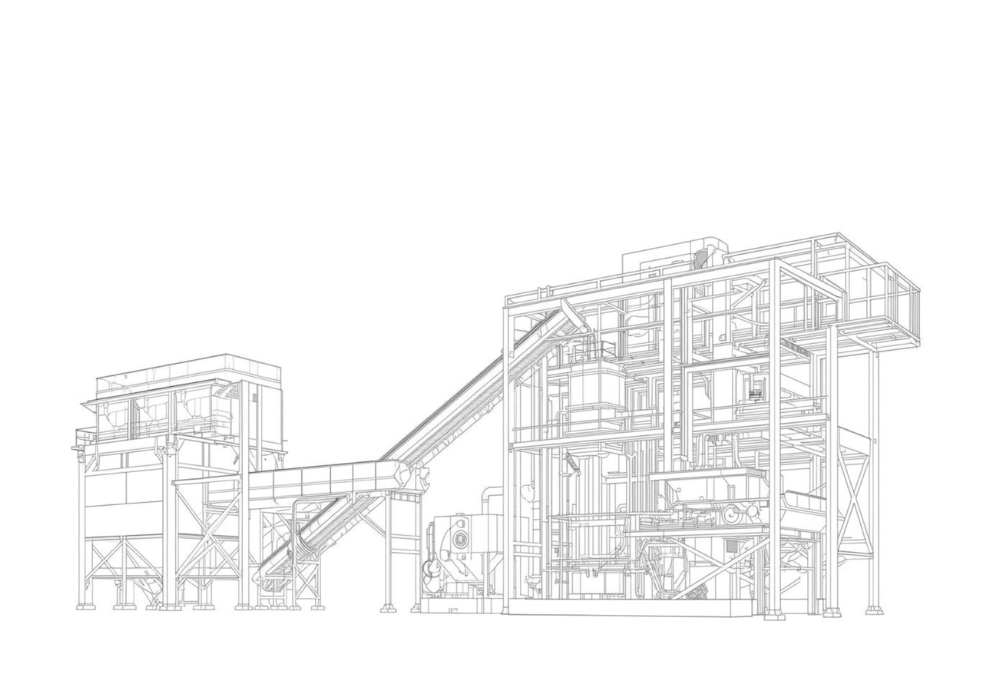

Our manufacturing capabilities are aligned with industrial equipment and custom system applications, covering CNC machining, welded structural assemblies and mechanical sub-assemblies adapted to defined technical requirements.

Submit your drawings and technical requirements. Our engineering team will review your request and provide a tailored quotation.