Positioning

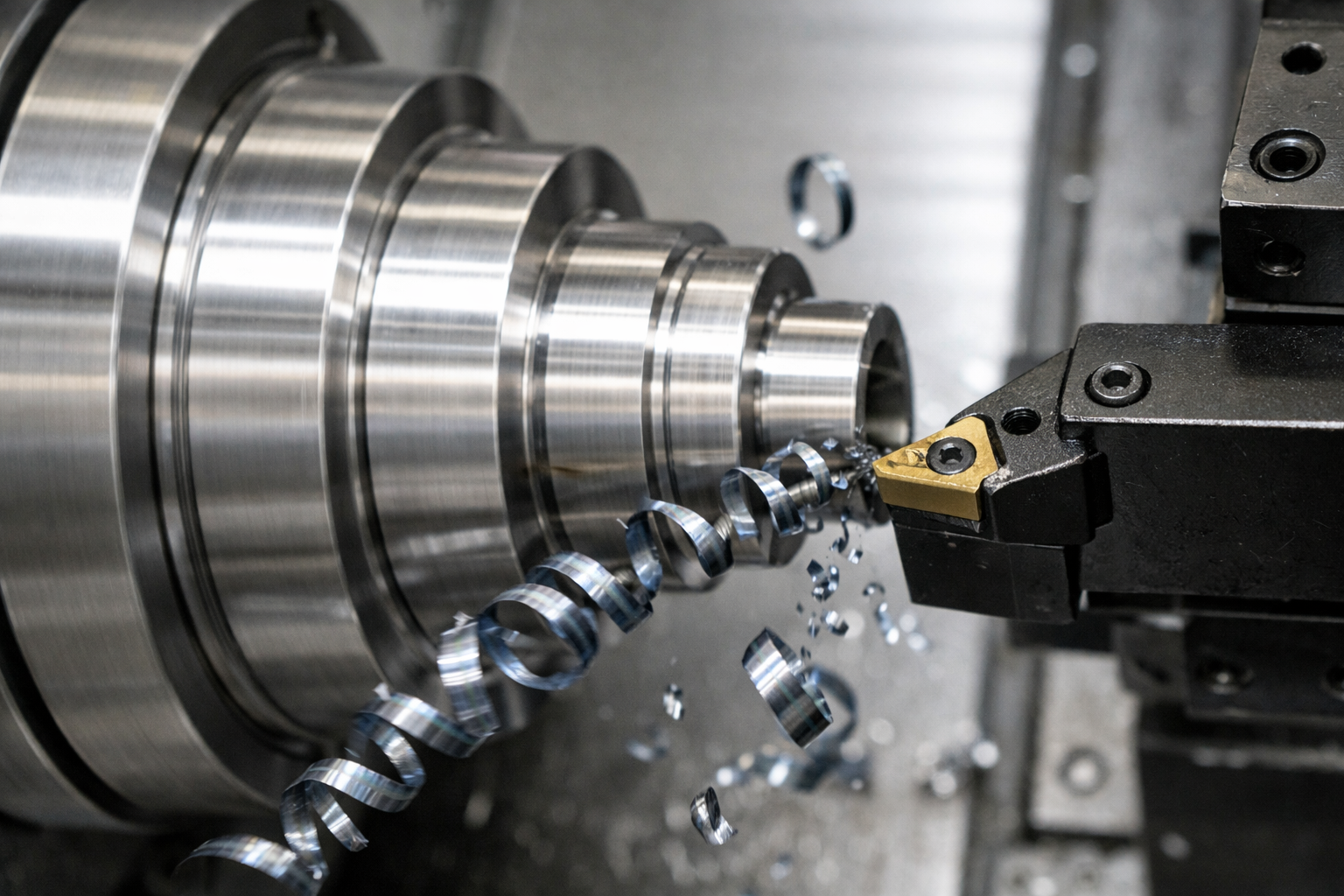

CNC turning positioned for function-critical cylindrical and rotational components where concentricity, coaxiality and stable process control drive assembly performance.

- Focus on controlled datum features, bearing seats and functional interfaces.

- Set up for RFQ evaluation and repeatable series production.