Positioning

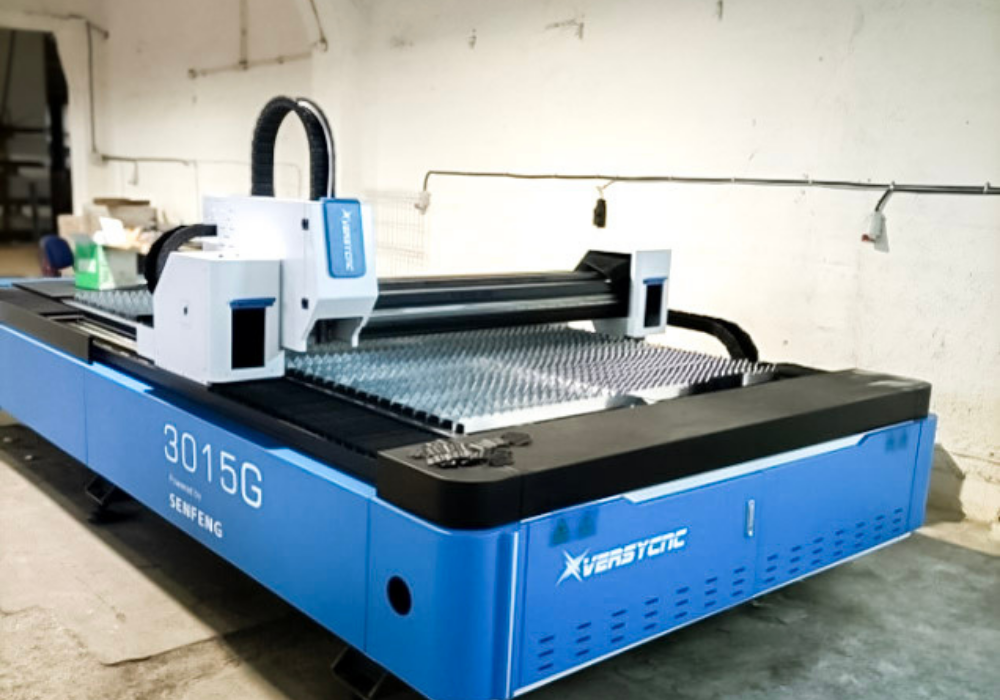

Sheet metal cutting positioned for structural plate and welded assemblies where cut quality, geometry fidelity and downstream welding/machining alignment are critical.

- Cut methods selected by thickness, tolerance intent and assembly requirements.

- Optimized for predictable fabrication flow: cut → weld → machine (where applicable).